Product introduction:

The precision desktop micro servo punch press has the characteristics of compact structure, superior performance, convenient operation, stable precision, safety and reliability. Widely used in electronics, instruments, automobiles, computers, cameras, jewelry, lamps and other industries, it can cut, punch, blank, bend, stretch, crimp, metal and non-metal sheets, strips, coils, etc. Processing of processes such as riveting and forming.

Key Features:

※ Using PLC as the control core + high-power servo drive system + precision ball screw pair and linear guide rod, it has the characteristics of simple operation, clear parameter display and high control precision.

※ It is suitable for stamping and precision static pressure in assembly line and CELL assembly line hardware/plastic/packaging material/material testing occasions.

※ Unique design, small size, light weight, high safety, suitable for frequently changing workplaces.

※ The parameters are all displayed in the interface design &, the punching speed adjustment range is large, and the precision punching & pressing operation can be performed in high-speed and extremely low-speed occasions.

※ The stamping data can communicate with the computer, which is convenient for data saving/querying and printing.

Product Features:

GF series of small table-top three-round guide post high-speed precision punch presses have precision and high stability. It has the superior performance of high and low speed noise.

1. The machine body is made of high-strength cast iron, the warp shaft is less deformed by force, and the bearings are imported high-precision bearings;

2. The crankshaft support is specially designed, the crankshaft is subject to small force and deformation, and the bearing adopts imported high-precision bearings;

3. The slider body is made of ductile iron, which has been quenched and tempered. The slider movement adopts the structure of double long guide columns combined with a large central guide column, which has strong bearing capacity and high running accuracy;

4. Slider automatic locking function (special model)

5. The reverse side load dynamic balancing device can effectively balance the vibration of the punching machine during high-speed operation and reduce the noise of the punching machine;

6. Pneumatic clutch brake system, reliable operation, forced circulation of lubricating oil device, to ensure stable precision of high-speed operation of the machine, extremely low wear of the machine, and long service life of the machine;

7. The humanized design of the whole punching machine, electronic monitoring system, can self-diagnose mechanical abnormal conditions, and display it on the screen.

|

Standard accessory configuration

|

|

Counter

|

1 group

|

|

Dry pneumatic clutch brake

|

1 group

|

|

Electronic cam construction

|

1 group

|

|

Inverter control

|

1 group

|

|

Manual mold height adjustment

|

1 group

|

|

Circulating lubrication oil supply system

|

1 group

|

|

Air source receptacle

|

1 group

|

|

Maintenance tools and toolboxes

|

1 group

|

|

Operating instructions and precision

|

1 group

|

|

Standard accessory configuration

|

|

Photoelectric protection configuration

|

1 group

|

|

Misfeed detection configuratior

|

1 group

|

|

Ocerload protection device

|

1 group

|

|

Automatic airblower

|

1 group

|

|

Roller feeder

|

1 group

|

|

Flat feeder

|

1 group

|

|

Precision Straightener

|

1 group

|

|

Oil pressure locking system

|

1 group

|

|

Irem\Model

|

GF-5A

|

GF-10A

|

GF-15A

|

|

nominal force

|

5T

|

10T

|

15T

|

|

Rated tonnage point

|

0.6

|

0.8

|

0.8

|

1.0

|

1.0

|

1.2

|

|

Stroke

|

20

|

30

|

40

|

50 |

20

|

30

|

40

|

50

|

60

|

20

|

30

|

40

|

50

|

60

|

70

|

|

Speed changing

|

200-

350

|

150-

300

|

150-

250

|

150-

200

|

200-

350

|

150-

300

|

150-

260

|

150-

220

|

150-

200

|

200-

350

|

150-

300

|

150-

270

|

150-

240

|

150-

210

|

150-

200

|

|

Die height

|

160-

190

|

155-

185

|

150-

180

|

145-

175

|

190-

220

|

185-

215

|

180-

210

|

175-

205

|

170-

200

|

200-

330

|

195-

225

|

190-

220

|

185-

215

|

180-

210

|

175-

205

|

|

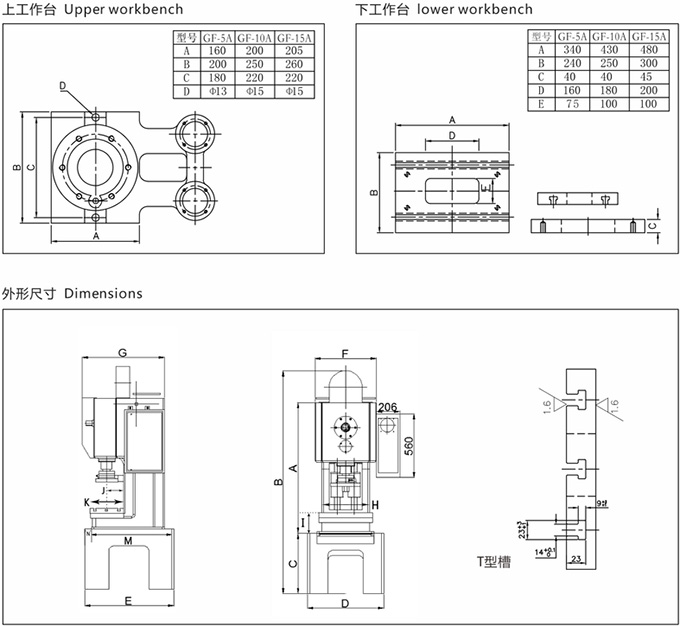

Slide area

|

200x160

|

250x200

|

260x205

|

|

Moid mogniSeihgleofupper

|

180mm

|

220mm

|

220mm

|

|

Bolster area

|

340x240x40

(lengthxwidthxheight)

|

430x250x40

(lengthxwidthxheight)

|

480x300x45

(lengthxwidthxheight)

|

|

Hole size of the filling

|

160x75

|

180x100

|

200x100

|

|

Slide Adjustment

|

30

|

30

|

30

|

|

Main motor

|

1.1

|

1.5

|

2.2

|

|

Dies can be installed

|

Hanging mode

|

Hanging mode

|

Hanging mode

|

|

Modulation mode

|

Manual

|

Manual

|

Manual

|

|

Strokemm type

|

Inching/route/continuous

|

|

Air pressure in use

|

5

|

5

|

5

|

|

method of operation

|

Bimanualness method

|

Bimanualness method

|

Bimanualness method

|

|

Fuselage(lengthxwidthxheight)

|

950x700x1680

|

1150x850x1870

|

1150x850x2000

|

|

Presses colour

|

Standard creamy white

|

Standard creamy white

|

Standard creamy white

|

|

presses Weight

|

640kg

|

1000kg

|

1300kg

|

|

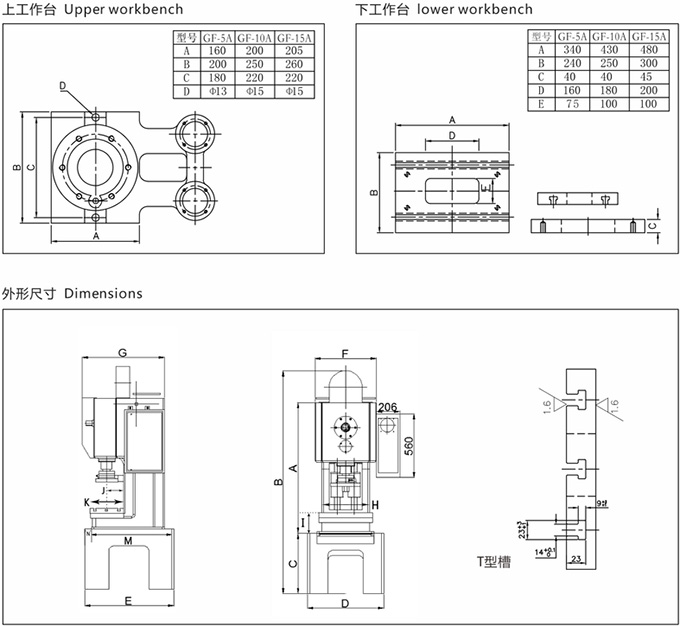

model

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

J

|

K

|

M

|

N

|

|

G F-5A

|

958

|

1693

|

515

|

500

|

600

|

380

|

570

|

285

|

190

|

120

|

240

|

480

|

60

|

|

G F-10A

|

1100

|

1840

|

460

|

650

|

750

|

480

|

715

|

390

|

180

|

125

|

250

|

600

|

70

|

|

G F-15A

|

1152

|

1962

|

530

|

670

|

790

|

540

|

730

|

425

|

195

|

150

|

300

|

660

|

75

|

Company Profile

Dongguan Gangfeng Precision Industry Co., Ltd. is a high-tech enterprise specializing in the development, manufacture and sale of high-speed precision punching machines. The company specializes in the production of GF-column small table-top three-round guide-post high-speed precision punching presses. The products are mainly used in metal stamping of precision electronics and electrical appliances, stamping of luggage hardware accessories, stamping of jewelry accessories, stamping of non-metallic parts and other industries.

The company has a group of professional senior technicians who have been engaged in the research and development and manufacture of stamping equipment for more than 20 years, and can customize non-standard stamping equipment according to the special needs of customers. Relying on rich industry experience, timely tracking and researching and developing the technological development and equipment performance requirements in the stamping field, drawing on the industry high-tech in Europe, America and Japan, R&D and development of GF series punching machine, the performance has reached the high-quality level of foreign counterparts, the structure is exquisite and stable, and the operation and easy maintenance.

The company specializes in the production of high-speed punches (3T-20T), and has large and large numbers of CNC machining equipment, various fine testing instruments, and a full set of physical and chemical facilities and other advanced quality control methods, realizing ERP, PDM, CAM and other enterprise information engineering, with the ability to respond quickly to market demand, the company adheres to the quality policy of "seeking quality, dedicated service", continuously improving the quality awareness and work quality level of all employees, clarifying quality goals and principles to follow, to ensure product quality. Advanced and reliable dominant position in market competition.

Gangfeng brand, confidence is guaranteed; because of professionalism, high quality can be achieved. In line with the goal of creating value for customers, we pursue excellence in quality and serve public innovation. Customers are welcome to buy, and to undertake special specifications of products required by customers.

|